Product Description

Product Description:

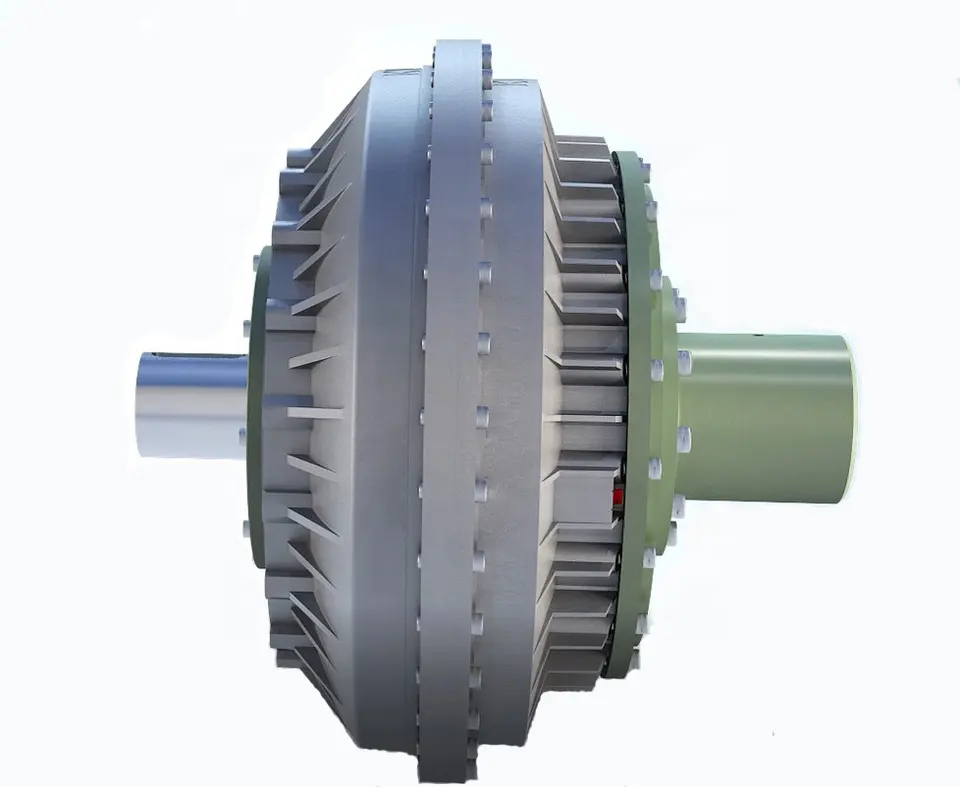

Coupling is used to link the 2 different organizations shaft (driving shaft and driven shaft) to rotate to common transmission torque of mechanical parts.The overloaded power transmission at high speed, some coupling and buffer, vibration and enhance the role of shaft system dynamic performance.Coupling consists of 2 parts, respectively, and the driving shaft and driven shaft connection.

| Brand | SHAC |

| Raw material | Aluminum |

| Inner Diameter | 4-60MM |

| Length | 25-140MM |

| Model number | JM1,JM2,JDM,JM-T,JH,TM1/TM2/TM3/TM4,JB,JG,JT |

| Packing | Plastic bag+inner box.According to customer’s request |

| Sample | Free sample and catalogue available |

| Certification | ISO 9001 , ISO 14001 , ISO 14000 |

| Application | CNC machines, medical and food machinery, fitness machinery, packaging machinery, printing machinery, and other machinery supporting equipment. |

Detailed Photos

Company Profile

Certifications

Our Advantages

Service:

1,Our Team:

We have experienced and qualified team of marketing and sales representatives to serve our valued customers with the finest products and unsurpassed service.And have professional engineers team to assessment and development the new precision products,and make the OEM customized more easily,experienced QC team to test the products quaity ensure the goods quality before delivery out.

2,Our products:

Quality is the life .We use only the best quality material to ensure the precision of our

Product.All products we sold out are strictly selected and tested by our QC department.

3,Payment:

We accept payment via TT (Bank transfer), L/C,Western Union.

4,Shipping method:

Including DHL, UPS, TNT, FEDEX,EMS, Airfreight and by Sea,as customer required.

To get sample or price list of linear gudies,ball screw, please contact us.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Best Practices for Selecting Oil for an Oil Coupling System

Selecting the appropriate oil for an oil coupling system involves considering various factors to ensure optimal performance and longevity:

- Viscosity: Choose an oil with the right viscosity grade for the operating temperature range to maintain proper lubrication.

- Load and Torque: Consider the system’s load and torque requirements to select an oil that can handle the anticipated stresses.

- Speed: Determine the operating speed range and choose an oil that can provide adequate lubrication at those speeds.

- Environment: Assess the operating environment for factors like temperature, humidity, and potential contaminants.

- Compatibility: Ensure the chosen oil is compatible with the materials used in the coupling and its components.

- Oil Life: Evaluate the oil’s expected service life and its ability to resist oxidation and degradation over time.

- Oil Additives: Consider additives that enhance lubricity, anti-wear properties, and resistance to foaming and corrosion.

- Manufacturer Recommendations: Consult the coupling manufacturer’s guidelines and recommendations for oil selection.

- Oil Change Intervals: Determine the recommended oil change intervals based on factors like usage and operating conditions.

- Oil Analysis: Regularly monitor the oil’s condition through analysis to ensure it remains within acceptable parameters.

- Regulations: Consider any industry regulations or standards that might specify oil requirements for the intended application.

By following these best practices, you can choose the most suitable oil for your oil coupling system, optimizing its performance and longevity.

Industry Standards and Guidelines for Oil Couplings

While there are no specific industry standards or guidelines exclusively dedicated to oil couplings, their design and usage often fall within broader standards related to mechanical power transmission components. Some relevant standards include:

- ISO Standards: International Organization for Standardization (ISO) standards, such as ISO 9001 for quality management systems and ISO 14691 for industrial fans, provide general guidelines that may apply to oil coupling manufacturers.

- AGMA Standards: The American Gear Manufacturers Association (AGMA) produces standards related to various types of mechanical power transmission equipment, which could encompass aspects of oil coupling design and manufacturing.

- API Standards: The American Petroleum Institute (API) develops standards for equipment used in the oil and gas industry, which may include guidelines for components like oil couplings.

Additionally, manufacturers and users of oil couplings should follow best practices, engineering principles, and guidelines for lubrication and maintenance to ensure optimal performance and longevity of the coupling.

Types of Oil Couplings for Specific Uses

Oil couplings come in different variations, each designed to suit specific applications and operating conditions. Some common types include:

- 1. Constant-Fill Fluid Couplings: These couplings maintain a constant level of fluid, providing consistent torque transmission and smooth operation. They are often used in applications requiring precise control and constant torque delivery.

- 2. Variable-Fill Fluid Couplings: These couplings allow for variable fluid levels, enabling adjustable torque transmission and speed control. They find applications in situations where speed modulation is essential, such as conveyors and certain industrial processes.

- 3. Start-Up Fluid Couplings: These specialized couplings provide high torque during startup, helping heavy machinery overcome initial inertia. Once the machinery is up to speed, the coupling allows for smooth and efficient power transmission.

- 4. Slip Torque Limiters: These couplings are designed to protect equipment from sudden overloads. They slip when the torque exceeds a preset limit, preventing damage to the machinery.

- 5. Centrifugal Couplings: These couplings use centrifugal force to engage and disengage the transmission of torque based on the rotational speed. They are commonly used in applications like lawn mowers and other small machinery.

- 6. Fan Fluid Couplings: These couplings are often used in cooling systems for fans and blowers. They allow for variable speed operation and protect the equipment from sudden load changes.

- 7. Torque Converters: While technically a type of fluid coupling, torque converters are commonly used in automotive applications. They provide variable torque multiplication and enable smooth shifting in automatic transmissions.

The choice of oil coupling type depends on factors such as the desired torque characteristics, speed control requirements, and the specific demands of the application.

editor by CX 2024-04-30

by

Tags:

Leave a Reply